Recently, Penno Technology, a company specializing in the R&D and production of high-end chemical materials, announced technological breakthroughs for three of its high-performance polymer products: Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (CAS: 155090-83-8),

Poly(sodium-p-styrenesulfonate) (CAS: 25704-18-1), and Ethylene-vinyl acetate copolymer (CAS: 24937-78-8). The launch of these technologically upgraded products not only enriches Penno Technology’s product portfolio in the polymer materials sector but also provides key material support for strategic emerging industries such as electronic information, new energy, and biomedicine, demonstrating the enterprise’s technological breakthroughs and innovative strength in the fine chemical industry.

Precisely Targeting Market Demands, Three Products Each Shine in Their Fields

Against the backdrop of the global conductive polymer market expanding at a compound annual growth rate (CAGR) of 8.4%, the three polymer products launched by Penno Technology accurately meet the high-end application needs of different sectors with their unique performance advantages.

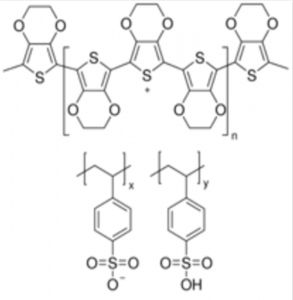

As a core product in the conductive polymer field, Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (abbreviated as PEDOT:PSS) exhibits outstanding comprehensive performance. Boasting high conductivity (minimum surface resistance up to 200Ω/cm²), excellent transparency, and stable thermal properties, the product addresses the industry pain point of traditional conductive materials—“the difficulty of balancing conductivity and transparency.” Its application scenarios cover cutting-edge fields such as flexible electronic screens, touch panels, and organic photovoltaic cells. Meanwhile, in the production of antistatic coatings, it can achieve an excellent surface resistance as low as 10⁸Ω/sq, providing a reliable electrostatic protection solution for electronic component packaging.

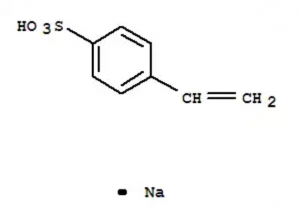

Poly(sodium-p-styrenesulfonate) stands out with core advantages of high purity, easy solubility, and strong chemical stability. As an important water-soluble polymer electrolyte, it is widely used in water treatment membrane preparation, pharmaceutical sustained-release formulations, dye dispersants, and other fields. In the production of polymer composites, the product can effectively improve the mechanical properties and dispersion uniformity of materials. Particularly in the preparation of conductive polymer composites, it significantly optimizes system compatibility, facilitating the R&D and application of high-performance composites.

The Ethylene-vinyl acetate copolymer (abbreviated as EVA) launched simultaneously covers diverse application scenarios through flexibly adjustable product characteristics. Based on the differentiated configuration of Vinyl Acetate (VA) content, Penno Technology’s EVA products can be applied to photovoltaic encapsulant films, high-end foaming materials, food packaging films, and automotive interiors, among other fields. Among them, EVA products with high VA content demonstrate excellent adhesion and weather resistance in photovoltaic module packaging, while products with low VA content, relying on good elasticity and processability, become ideal materials for the footwear industry and automotive sealant production, fully meeting the development needs of the new energy and transportation lightweight sectors.

Technology-Driven Quality Upgrading, Consolidating Industrial Competitive Advantages

www.pengnuochemical.com

Shijiazhuang Pengnuo Technology Co., Ltd.

The process improvement of Penno Technology’s three polymer products is inseparable from the enterprise’s continuous investment in R&D and production. According to the R&D Director of Penno Technology, the company has established a full-chain production system from monomer synthesis to polymer polymerization. By introducing high-precision reaction control technology, it has achieved precise regulation of key indicators such as product molecular weight distribution and purity. Taking PEDOT:PSS as an example, the product purity reaches over 99%, far higher than the industry average, enabling direct application in the manufacturing of high-end electronic devices.

In the production process, Penno Technology strictly adheres to the concept of green chemistry and adopts a closed-loop production process to minimize energy consumption and pollutant emissions during production. Among them, the EVA product production adopts solvent-free polymerization technology with no harmful gas emissions throughout the process, fully complying with national environmental protection standards and providing downstream enterprises with green and environmentally friendly material options.

Layout in the High-End Material Track, Empowering High-Quality Industrial Development

Currently, the global polymer materials industry is transforming towards high performance, functionalization, and greenization. The rapid development of China’s electronic information, new energy, and other sectors has created an urgent demand for high-end chemical materials. Penno Technology’s concentrated launch of three high-performance polymer products is an important measure for the enterprise to respond to market demands and layout in the high-end material track.

The General Manager of Penno Technology stated: “Conductive polymers and high-performance copolymer materials are key basic materials supporting the development of strategic emerging industries. The launch of these three products not only reflects Penno Technology’s R&D strength but also demonstrates our responsibility to assist downstream industrial upgrading. In the future, the company will continue to focus on technological innovation in the polymer materials field, continuously expand the application boundaries of products, and provide more competitive material solutions for global customers.”

It is understood that Penno Technology has already reached cooperation intentions with a number of electronic manufacturing enterprises, photovoltaic companies, and pharmaceutical R&D institutions. The three polymer products will be gradually applied to practical production scenarios such as flexible displays, photovoltaic module packaging, and pharmaceutical sustained-release formulations. With the full market launch of the products, Penno Technology will further consolidate its industry position in the high-end chemical materials sector and inject new momentum into the high-quality development of China’s fine chemical industry.

About Penno Technology

Penno Technology is a high-tech enterprise specializing in the R&D, production, and sales of high-end fine chemical products. Its core products cover pharmaceutical intermediates, functional additives, high-performance polymers, and other fields. The company has a comprehensive R&D system and large-scale production capacity. With stable product quality and professional technical services, its products are widely used in pharmaceuticals, electronics, new energy, new materials, and other sectors. Penno Technology is committed to becoming a world-leading provider of fine chemical material solutions.

Post time: Dec-02-2025